_

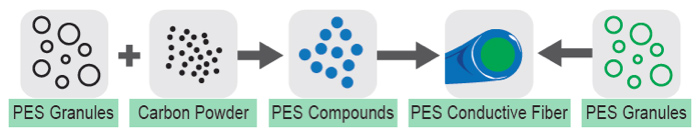

Conductive fibers / Shakespeare (USA)

Shakespeare’s combination of technologically advanced engineering, materials selection, and precision manufacturing

produces specific and often unique monofilaments and polymers for industries and applications of all kinds.

F902 R022 (PA6) TDS

| Product | F902 R022 |

| Denler | 22 |

| D’tex | 24 |

| Tenacity | 5 grams / denier |

| Elongation at Break | 41% |

| Product Yield | 202,931 yard per pound / 409,091 meters per kilogram |

| Resistivity Average | 4 x 10(5) ohms / centimeter |

| Mineral Acids, Cold | Good resistance |

| Mineral Acids, Hot | Poor resistance |

| Concentrated Mineral Acids | Poor resistance |

| Alkalie | Good resistance |

| Solvents | Good resistance (except Phenolic) |

| Formlc Acid | Dissolves |

| Water / Hydrolysis | Good resistance |

| Melting point | 220℃ |

Polyester grades and TDS

| Product | P6203 | P6203 | P6203 | P6204 | P6303 |

| Color | Black | Black | Black | Black | Black |

| Type | Filament | Filament | Filament | Filament | Twist Yarn |

| Denier / Filament | 20/6 | 40/12 | 75/24 | 100/24 | 20/6+75 Den PES |

| Tenacity grams / denier | 3 | 3 | 3 | 3 | 4 |

| Elongation at Break | 60% | 60% | 60% | 60% | 45% |

| Resistivity Average (ohms / cm) | 10^6 | 10^6 | 10^6 | 10^6 | 10^6 |

| Product | P6103 | P6106 |

| Color | Black | Black |

| Type | Staple | Staple |

| Construction / Denier per Filament | 3dpf | 6dpf |

| Tenacity grams / denier | 3 | 3 |

| Elongation at Break | 72% | 72% |

| Resistivity Average (ohms / cm) | 10^6 | 10^5 |

| Cut Lengths (mm) | 38, 50, 75 | 38, 50, 75 |

Applications

_

ESD work wears, carpets and anti-static brushes

_

Anti-static wears, flame retardant workwears and formal wears