_

Cellasto / BASF (Germany)

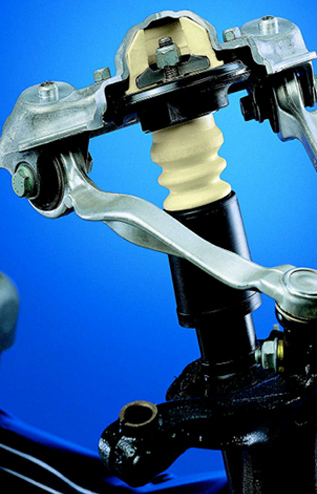

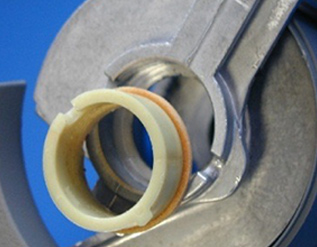

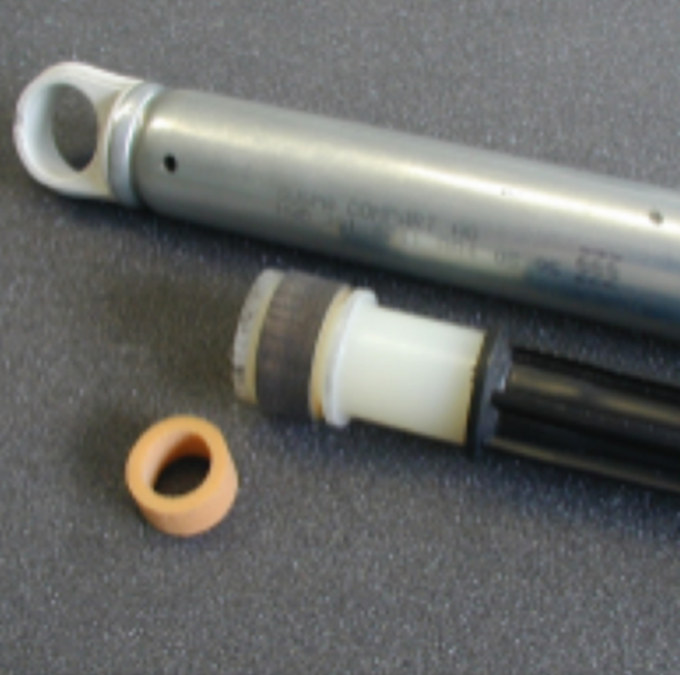

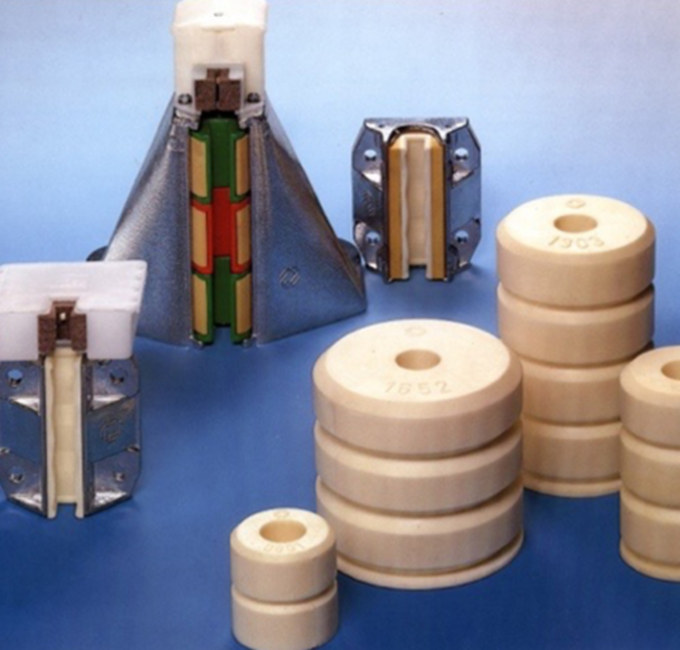

Cellasto components are based on a cellular polyurethane elastomer. The moulded components are produced in

a closed-mould foaming process. They are high resilient spring- and damping elements with the following

characteristics: high compressibility, low compression set, very good static and dynamic long-run behavior, wide

application area from -30°C to +80°C ambient temperature and excellent durability and chemical resistance.

Characteristics

– Low compression set

– Very good static and dynamic long-term behavior

– High abrasion-resistance

– Ozone-resistance

– High volume compressibility with minimum lateral expansion

– Cadmium-free

Technical datas

| Material | Cellasto MH – micro-celluar polyurethane elastomer -mikrozelliges Polyurethan Elastomer |

|||||||

| 1 | Density / Dichte [g/cm3] (DIN EN ISO 845) |

0,35 | 0,40 | 0,45 | 0,50 | 0,55 | 0,60 | 0,65 |

| 2 | Tensile Strength / Zugfestigkeit [N/mm2] (DIN ISO 1798) |

3,6 | 3,6 | 5,0 | 5,7 | 6,3 | 7,0 | 7,2 |

| 3 | Elongation at Break / Brunchdehnung [%] (DIN ISO 1798) |

350 | 380 | 420 | 430 | 460 | 470 | 480 |

| 4 | Tear Resistance / Weiterreisswiderstand [N/mm] (DIN ISO 1798) |

10,0 | 13,5 | 14,0 | 18,0 | 20 | 21 | 22 |

| 5 | Impact Resilience / Ruckprallelastizitat [%] (DIN 53 512) |

53 | 53 | 54 | 54 | 54 | 56 | 56 |

| 6 | Compression Set / Druckverformungsrest [%] 70 h / +23℃ (DIN EN ISO 1856) |

2,6 | 2,7 | 2,7 | 2,8 | 2,8 | 3,0 | 3,0 |

| 6.1 | Compression Set / Druckverformungsrest 70 h / +70℃ (DIN EN ISO 1856) |

3,5 | 3,6 | 3,8 | 3,9 | 4,2 | 4,6 | 4,6 |

| 6.5 | Compression Set / Druckverformungsrest 22 h / +80℃ (Elastogram Spec. AAU-10-131-035) |

14 | 15 | 15 | 17 | 18 | 19 | 19 |

Applications

_

Automotive parts

_

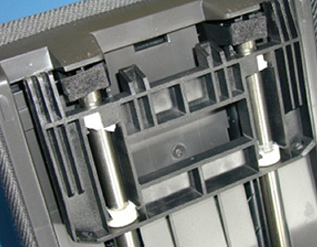

Home appliances

_

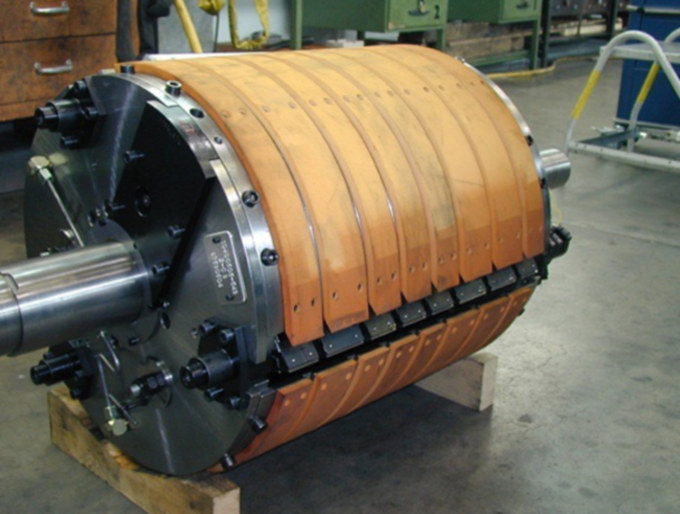

Rollers and transfer equipment

_

Elevator

_

Office chairs

_

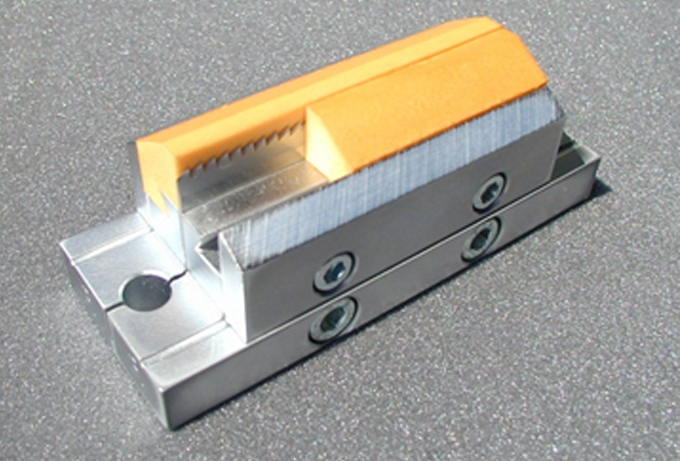

Die and pressure bar

_

Gantry crane and bicycle